Bibwewadi, Pune, Maharashtra

1 Piece (MOQ)

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Suitable For | Charpy - Tests |

| Initial potential energy (Joules) | 300 |

| Minimum scale graduation for AIT-300-ASTM(Joules) | 2 |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

Resolution for AIT-300-ASTM (D) (Joules)

0.5

Pendulum drop angle (degree)

140

Stiking velocity of pendulum (m/sec)

5.182

Distance between axis of rotation and centre of strike (length of pendulum) (mm)

775

Effective weight of pendulum (kg)

22.35

Total friction and windage losses of maximum Impact energy (%)

0.75 Max

Distance between physical percussion centre of pendulum and centre of Charpy specimen(mm)

+7.75 Max

Striking edge (Angle of striking edge (degree))

30 +/- 2

Striking edge (Radius of striking edge(mm)

8 +/- 0.05

Striking edge(Width of tip (mm))

4

Suitable for specimen size (mm)

10x10x55

Distance between Anvils (mm)

40 +/- 0.05

Angle of anvil (degree)

80 +/- 2

Radius of supports (mm)

1 +/- 0.05

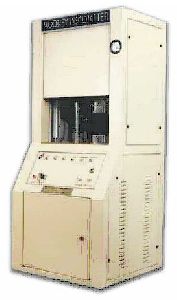

Overall size (mm) approx

930(L)x460(W)x2070(H)

Net weight (kg) approx

500

Impact Testing Machines As per BS, ASTM and ISO Standard for Metal, Nonmetal and plastics range 2.71 Joule to 500 Joule capacity.

Features:

- For charpy tests on various materials.

- Strictly conforms to ASTM-E-23-2007 specifications.

- Works on pendulum principle. Difference between height of drop of pendulum before rupture and height of rise after rupture of specimen is directly proportional to impact energy absorbed by specimen and is indicated by a pointer on a large dial for Model-ASTM & on Digital Display for Model- ASTM (D).

- Single stand design which facilitates fast and easy positioning and centering of specimen which is a basic requirement of sub-zero testing.

- Unique spring loaded braking system for smooth and jerk free braking.

- NIST approval of machine with samples from NIST-USA. Can be arranged.

- Digital version of ASTM model will be available soon.

OPTIONAL ACCESSORIES:

- Self centering tong for Charpy test specimen (useful particularl for carrying out tests at sub zero temperature).

- Sub zero temperature bath with digital temperature indicator.

- Go: No-Go gauges for conforming the following parameters of specimen-within the limits specified by the standard.

- Center line of notch from both ends.

- Angle of V notch.

- Depth below standard V notch

- Cross section of 10x10 mm specimen.

- Milling cutter for V notch.

- Charpy & Izod notch (V&U) broaching machines.

- Lateral expansion gauge as per ASTM-E-23.

- Standard impact specimen for verifivcation of machine from NIST-USA (we also undertake calibration of the machine as per ASTM-E-23 including approval from NIST-USA).

Looking for "Impact Testing Machine" ?

piecesPiece

Explore More Products