| View Mobile Number Call Us |

| Business Type | Manufacturer, Exporter, Supplier |

Details:

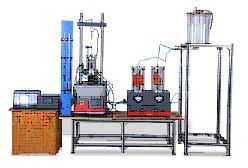

- Heat Treatment Furnaces for Various application Annealing , Normalising

- Hardening , Solution Treatment Heating , Forge Heating , Tempering

- Aluminum Solutionising , Stress Relieving , Ductile Iron Full Annealing

- Strong rigid construction , Heat resistant grade CI castings at door and frame, bogie and furnace interface eliminates warpage. Railway rails for load bearing under temperature. Double sealing minimizing heat losses

- Thermal survey as per API 6A Standard.

- All measuring instruments calibrated to national traceability

- With as per the Required AUTOMATION.

Applications

- Annealing

- Normalising

- Hardening

- Solution Treatment Heating

- Forge Heating

- Tempering

- Aluminum Solutionising

- Stress Relieving

- Ductile Iron Full Annealing.

Auto cycle control

- Ramp, Soak, Cool ..... 8 Steps Profile

- 10, 20 Profile Memory

- Multi Input Multi Output (MIMO)

- PID Controlling Action.

- Micro processor based programable controller.

- one burner, one thermocouple forms one pair as zone, thus multi zone control

- Digital display for time temprature graph online with USB pendrive for data storage, Wired lan PC connectivity for real time graph printing

Firing

- High Velocity Short Flame Burner

- Direct On/Off pulse firing effect.

- Smokeless perfect combustion

- The furnaces are calibrated for uniformity as per API 6A Standard ( The Temperature Difference Between Highest & Lowest Points at Stabilised Conditions should not be more than 13ºC.)

Mechanization

- Trolley - movement by geared motor with brake.

- Door - movement by geared motor with brake, counter weighed,

- Door Lock Unlock - innovative,Pneumatically operated instant latching unlatching for perfect sealing

Construction

- Strong rigid construction

- Heat resistant grade CI castings at door and frame, bogie and furnace interface eliminates warpage.

- Railway rails for load bearing under temperature.

- Double sealing minimising heat losses.

Insulation

- High temperature high density ceramic fibre modular lining.

- Self supporting U-fold door lining.

Recuperator

All fuel fired furnaces are equiped with recuperator to recover the heat from flue gases by preheating combustion air. By thumb rule a rise of 150 degree C in combustion air 7.5% heat is recovered.

PLC control

- Large furnaces handle high value materials, it is essential to install PLC for opration to avoid manual errors.

- PLC checks each & every operation prior to loading of materials called booting to ensure air/gas/power etc. are within the specifications & all the sensors are in working condition

- PLC monitors each & every operation during auto cycle for supply conditions, flue temperatures burner operations any deviation is automatically notified audio visualy & through SCADA

- PLC keeps event history for the record

Control Panel

- Aesthetically powder coated control panel.

- Electrical switch gears for drives, burners.

- Status indication and control.

- Burner sequence controller and flame failure device.

- Programmable startup, burner, temperature controlling system.

Calibrations

- Thermal survey as per API 6A Standard.

- All measuring instruments calibrated to national traceability

Looking for "Heat Treatment Furnace" ?

Piece

Explore More Products